The resonance frequencies of an arbitrary object, structural parts or products are defined by their geometry, mass distribution and stiffness distribution. Even very small changes in geometry, mass or stiffness distribution will influence the value of the resonance frequencies. The spectrum of resonance frequencies can hence be regarded as a fingerprint of an object.

Checking the resonance frequencies (usually only the first fundamental frequency) gives valuable information about the quality of the object. In a production environment it allows to reject or approve an arbitrary product. Additionally, for many products like tiles, sporting goods, music instruments, the resonance frequency allows ranking.

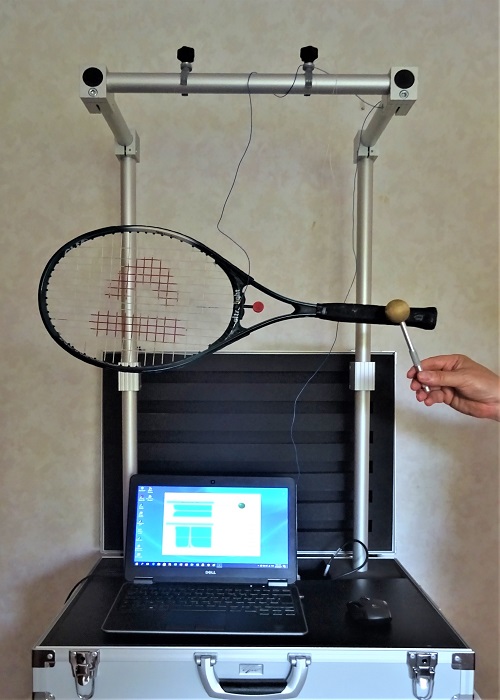

Example 1. Ranking of Tennis rackets

The dynamic stiffness is an important playability property of a tennis racket. The dynamic stiffness controls the vibrational behavior of a racket and is therefore an important value for the precision and comfort of the racket. Dynamic stiffness can be directly related to the first bending resonance frequency of the racket. A high value of the resonance frequency means a high dynamic stiffness of the racket. As an example, an extensive list of resonance frequencies of tennis rackets from different brands can be found eg.on URL

http://twu.tennis-warehouse.com/cgi-bin/vibfrequency.cgi

Measuring the Resonance Frequency of a Tennis Racket

The resonalyser equipment allows a fast, accurate and easy measurement of the resonance frequency of a racket. The racket is freely suspended on a frame. A small accelerometer is fixed in the middle of the racket with bees wax. Hitting the racket with an arbitrary object like a small hammer or a pencil immediately allows to read the value of the resonance frequency on the screen of the computer. The resonalyser equipment is portable and can be used in tennis clubs and tennis shops.

In a production environment, the frequency of the racket can be measured for quality control purposes. Indeed, every variation in the used material properties or errors during the assembly cause a different frequency. If the frequency deviates too much from the expected frequency of a normal good racket, the racket can be rejected. In this way the product brand can avoid a bad reputation.

The same facts of course count for other sporting goods like golf sticks, baseball bats, skis, badminton rackets etc.

Example 2. Quality control of glass bottles

The starting point for the use of resonance frequencies for quality control of products is to establish the relation between important properties of the product and its resonance frequencies.

An example used in the glass manufacturing industry is the quality control of glass bottles. With a finite element model of a bottle it can examined how the resonance frequency change as a function of local variations of the glass wall thickness.

- Finite Element Model of a Glass Bottle

- Measuring the Resonance Frequency of a Glass Bottle

If the wall thickness in some positions becomes too small, the resistance of the bottle for internal pressure, impact and capping forces can become unacceptable. The quality control manager can establish an acceptance interval for the resonance frequencies. Outside this interval the bottles are unacceptable and can be rejected. Regular control of the resonance frequencies of test batches of bottles can prevent the production of poor bottles with unacceptable mechanical properties.

The resonance frequencies of a freely suspended bottle can be easily measured with the resonalyser equipment. An accelerometer, a laser beam or a microphone can be used as measurement sensor.

Example 3. Quality control of concrete cylinders

Humidity, temperature, hardening time and composition all have a big influence on the quality of concrete. The Young’s modulus is a major value to judge the quality of concrete. The Young’s modulus of concrete beams of all sizes can be identified by measuring the resonance frequency of the axial vibrations of a test beam by the resonalyser equipment.

The size of test beams can range from tons towards a few grams!

- Testing a small 200 gram concrete cylinder at CRIC (Belgium Concrete Research Institute)

- Testing a 2 ton concrete cylinder in Labo Magnel (Ghent University)

Example 4. Roof and floor tiles

Cracks or voids in ceramic tiles immediately cause a variation in their resonance frequencies. The frequency of tiles can be measured by supporting them on soft pads.

Floor and Roof Tiles