Are you a Material Scientist or Manufacturer or an Engineer? The knowledge of the Elastic Engineering properties of materials is important for you! The Resonalyser instrument can identify Engineering constants based on measured Resonance Frequencies on Beams and Plates. This method is the most accurate, fast and cheap existing method at the moment! The basic working principles are explained in this 9 minutes video.

Resonalyser Instrument

Companies and research institutes equipped with Tensile Benches

Tensile benches are – among others- used to perform tensile and pressure tests and 3- or 4 point bending tests for measuring the Engineering constants and failure stresses.Dog bone or beam like test specimens are equipped with strain gauges for recording the strain as a function of the applied force. Test on Tensile Benches are executed by highly skillful and trained operators in order to obtain reliable results. However, strain testing is expensive! See video: Replacing strain testing.

Tensile benches are – among others- used to perform tensile and pressure tests and 3- or 4 point bending tests for measuring the Engineering constants and failure stresses.Dog bone or beam like test specimens are equipped with strain gauges for recording the strain as a function of the applied force. Test on Tensile Benches are executed by highly skillful and trained operators in order to obtain reliable results. However, strain testing is expensive! See video: Replacing strain testing.

Replacing strain testing

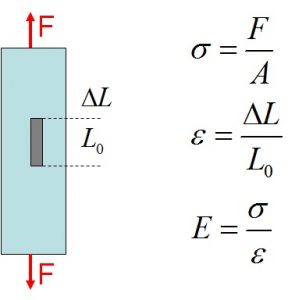

The figure on the right shows how the Young’s modulus E can be found by dividing the stress (Force F divided by cross section Area A) by the strain (elongation divided by original length L0)

By identifying the Engineering Constants with the non-destructive Resonalyser procedure as a first step, the Tensile Bench can be used for measuring the Failure Strength on beam specimens as a second step without having the need for fixing Strain gages, hence saving time and cost. The combination “Tensile Bench / Resonalyser” can hence deliver all the important information for a full Engineering Analysis of Products and Structures.

Engineers needing Engineering Constants for simulation models

Simulation models for mechanical properties of arbitrary products or structures require the input of the material Engineering Constants. Finite Element models need material properties averaged over the element areas.

The Resonalyser procedure yields averaged values over the test plate area and delivers hence suitable “Finite Element Friendly” results.

Companies producing sheet materials

Companies producing plastics, metals, ceramics, foams, … need constant testing of new material compositions and regular quality control. With the Resonalyser procedure hundred of tests can be performed every day. The procedure is fast, simple and accurate and needs no highly trained operators.

Universities and Technical educational institutes

The resonalyser instrument is very robust and affordable and allows laboratory experiments for students to increase their skills and understanding of Dynamics, Modal Analysis, Data Acquisition, Finite Elements, Inverse Methods, … among others.