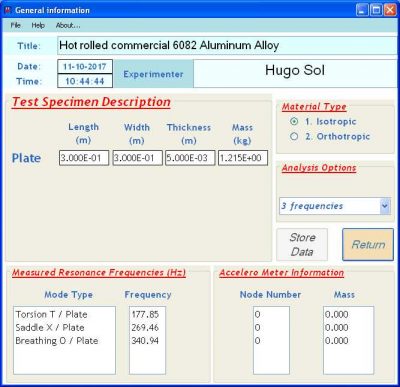

Description: Hot rolled commercial 6082 Aluminum Alloy considered as Isotropic Material

Size of the square test plate: 0.3 m x 0.3 m x 0.005 m

Weight: 1.215 kg

- Diagonal suspension

- Vertical suspension

The resonance frequencies of the torsion and breathing mode shapes can be measured in the most easy way by suspending the test plate diagonally. Fixing the accelerometer in a corner of the plate and tapping with a hammer in (another) corner activates mainly the torsion and the breathing mode shape. Hitting the plate in the center will activate only the breathing mode shape.

The resonance frequency of the saddle mode shape can be measured in the most easy way by suspending the test plate straight. Fixing the accelerometer in the middle of an edge of the plate and tapping with a hammer in the middle of (another) edge activates mainly the saddle mode shape.

The resonance frequencies can also be measured with a Microphone or a Laser Vibrometer. In those cases, no correction of the accelerometer mass is necessary. However, a measurement microphone or a laser Vibrometer are considerably more expensive than accelorometers and also require more experimental skills. In this example, the frequencies were measured with a microphone.

The measured frequencies for the square Aluminum sheet are:

- Torsional Modeshape: 177.8 Hz

- Saddle Modeshape: 269.5 Hz

- Breathing Modeshape: 340.9 Hz

After measurement of the frequencies and input of the geometrical data of the test plate, the general data screen of the Resonalyser program looks like:

General Data Screen of the Resonalyser Software

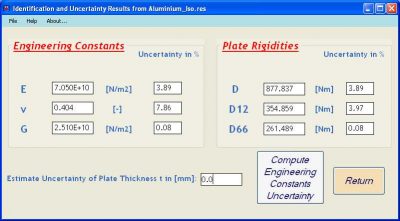

The figure below shows a screenshot of the obtained result screen for the Aluminum plate with the Engineering Constants E (Young’s Modulus), v (Poisson’s ratio) and G (In-plane Shear Modulus), the plate rigidities D, D12 and D66 and uncertainty bounds on the identified plate rigidities. The plate rigidities for isotropic materials are (t = plate thickness):

Results of the Resonalyser Procedure

Isotropic Engineering Constants of Aluminum and their Uncertainty bounds

The computed uncertainties on the plate rigidities (and hence on the Engineering constants) are rather high. This indicates that the assumption that the plate material behaves isotropic was approximate. A summary report of the data and the results is automatically stored in a .TXT File. Because the plate rigidity D of an isotropic material has the same in all directions, a square test plate qualifies as “Poisson plate”. The report file for this example is given below.