Many wood based materials (Chip boards, particle boards, multiplex boards, veneer, … ) show Orthotropic material behavior. This means that the elastic values have a mirror symmetry with respect to two perpendicular axes, the so-called “Material axes”. In the picture below these material axes are indicated as the (1, 2) axes and are parallel with the edges of the test plates.

The stiffness behavior of orthotropic wood based plates can be described by 4 Engineering Constants:

- The Young’s Modulus E1 in the 1-direction (Main orthotropic material axe)

- The Young’s Modulus E2 in the 2-direction (Perpendicular orthotropic material axe)

- Poisson’s ratio v12 (In plane coupling material property)

- Shear Modulus G12 (In plane shearing material property)

To make good test plates for veneers, several layers of Unidirectional veneers can be glued together on top of each other. One must careful to orient all layers in the same direction (parallel to the plate edges) to preserve the Orthotropic character of the final veneer test plate.

Beams and Plates of Wood based Materials

For orthotropic test plates, the resonalyser procedure works as follows:

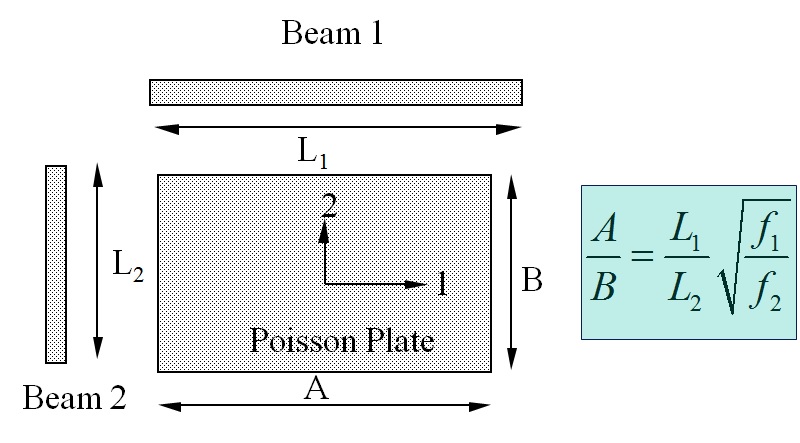

1. Measurement of the basic bending frequencies f1 and f2 of two beams cut along the sides of the test plate.

The basic bending frequencies of Beam 1 (f1) and Beam 2 (f2) together with the Beam Lengths L1 and L2 provide the correct aspect ratio A/B for a so-called “Poisson” Plate using the above formula.

Link to beam measurement

This allows cutting the test plate in the correct aspect ratio A/B for a “Poisson” plate. A Poisson plate is sensitive for all the orthotropic engineering constants and can hence identify all the engineering constants with the highest accuracy.

2. Measurement of the 3 first resonance frequencies of the Poisson plate

Link to plate measurement

Example: Orthotropic Multiplex plate

The resonalyser procedure is illustrated in the example: Example Multiplex Plate